Containerized water treatment plants have emerged as a game-changer in the field of water purification. Their compact design and efficiency make them invaluable in various settings, from remote areas with limited infrastructure to rapid response situations during emergencies. In this detailed guide, we will explore each component that constitutes a containerized water treatment plant, shedding light on its specific function and significance in the water treatment process.

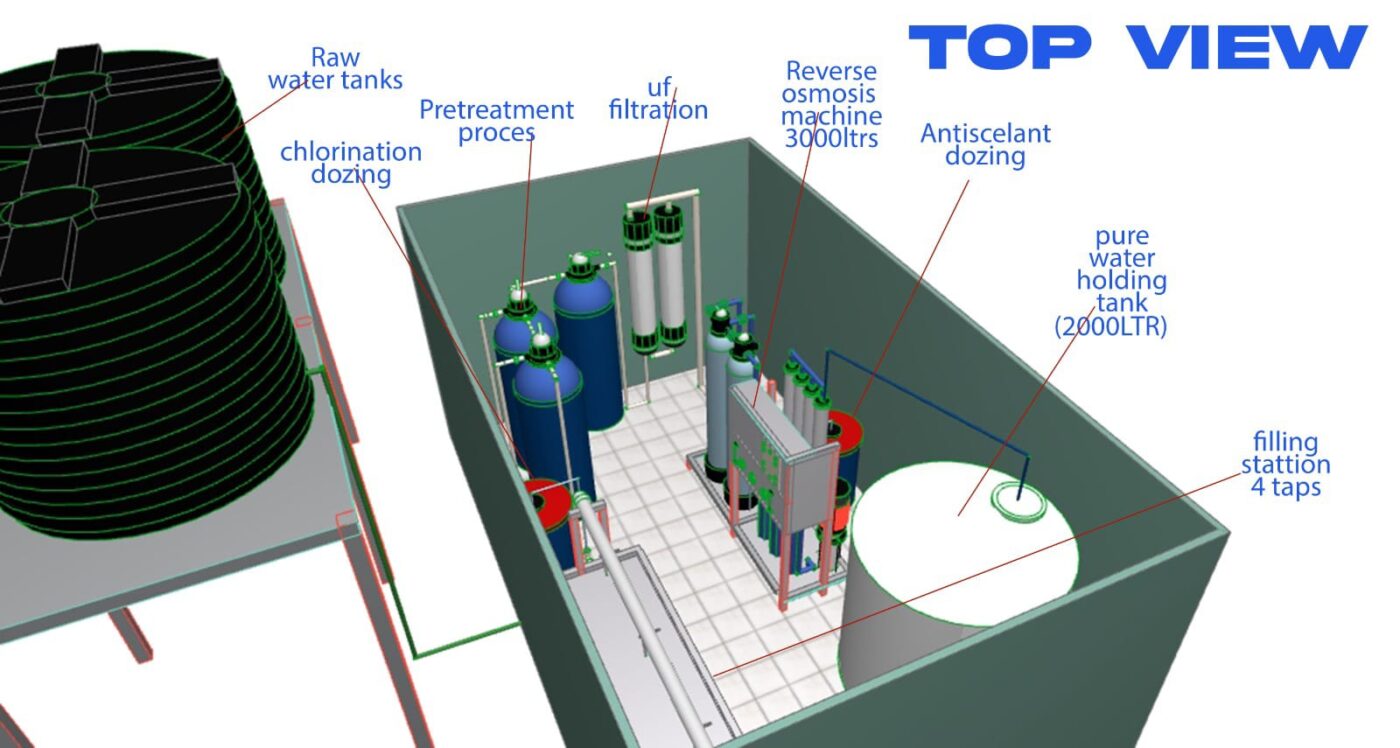

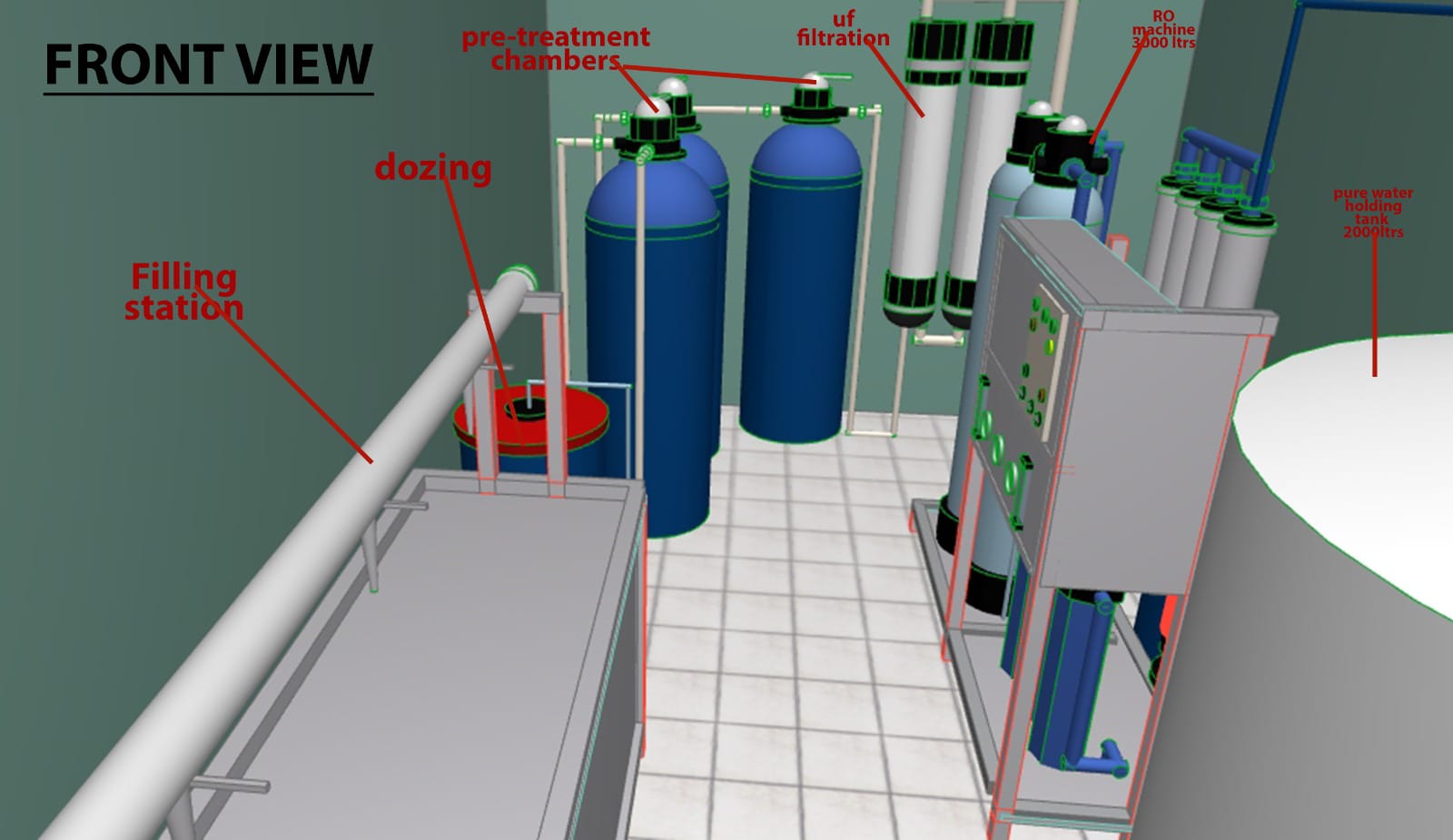

1. Automated Dosing Pumps: Precision in Chemical Treatment

Automated dosing pumps are the workhorses of a containerized water treatment plant. They are designed to precisely and consistently dispense treatment chemicals into the water. This precision is crucial, as it ensures that the correct dosage of chemicals is introduced, optimizing the purification process.

Dosing Tanks: Reservoirs of Treatment Chemicals

Dosing tanks are where the treatment chemicals are stored and mixed before being pumped into the water. They serve as controlled environments for the chemicals, allowing for effective blending and distribution. The tanks are equipped with agitators to ensure thorough mixing, guaranteeing that the chemicals are uniformly distributed.

2. Raw Water Pumps with Control Panels: Initiating the Process

Raw water pumps are the initiators of the treatment process. Their primary function is to draw water from its source and transport it into the treatment system. The control panels are the command center for these pumps, regulating their operation at the required flow rates and pressure levels. This ensures that the water is moved through the system efficiently.

Media Filtration Vessels: Tailored Filtration for Raw Water

Media filtration vessels are integral to the treatment process. They are designed based on the specific characteristics of the raw water. These vessels house various types of filtering media, such as sand, gravel, or anthracite, which remove impurities, sediments, and contaminants from the water. The selection of media is tailored to the composition of the raw water, ensuring optimal filtration.

3. Ultraviolet Sterilizer: Harnessing UV Power

The ultraviolet (UV) sterilizer is a critical component that employs the power of UV light to disinfect the water. The UV lamps emit a specific wavelength that is lethal to microorganisms, effectively neutralizing bacteria, viruses, and other pathogens. This step is essential for making sure the water is safe to drink.

4. Startup Chemicals and Media: Customized for Quality

The selection of startup chemicals and media is a pivotal decision in the treatment process. It is determined by the quality of the raw water. Factors such as pH levels, hardness, and the presence of specific contaminants dictate the choice of chemicals and media. This customization is essential for achieving optimal results in the treatment process.

5. Ozone Generator: Enhancing Disinfection

The ozone generator is a powerful tool in water treatment. It introduces ozone (O3) into the water, which is a highly effective oxidizing agent. Ozone is capable of breaking down organic contaminants, bacteria, and viruses. This additional step enhances the overall disinfection process, ensuring that the water is of the highest quality.

6. Industrial Reverse Osmosis System: Purification at Its Finest

The industrial reverse osmosis (RO) system is a cornerstone of water purification. It utilizes semi-permeable membranes to remove a wide range of impurities, including salts, minerals, and dissolved solids. This process results in water of exceptional purity, making it suitable for various applications.

7. Ultrafiltration Membranes: Finer Filtration for Purity

Ultrafiltration membranes operate on a finer scale compared to media filtration. They are capable of capturing even smaller particles and microorganisms. This additional filtration step further refines the water quality, ensuring that it meets the required standards for consumption or industrial use.

8. Safety Pressure Switches: Monitoring for Security

Safety pressure switches serve as vigilant guardians of the system. They continuously monitor the pressure levels within the plant. In the event of abnormal pressure fluctuations, these switches trigger alarms or shut down specific components, preventing potential hazards and ensuring the safety of the operation.

9. Micro or Sediment Filtration: Additional Purification Layers

Microfiltration or sediment filtration provides an extra layer of purification. This step is particularly effective in capturing minute particles that may have bypassed previous filtration stages. It acts as a safeguard, further enhancing the overall water quality.

Sizing Considerations: Matching Capacity to Demand

The sizes of filters, vessels, and membranes are determined by the volume of water to be treated. This crucial step ensures that the plant can handle the required capacity efficiently. Sizing considerations are based on flow rates, water quality parameters, and the specific demands of the application.

Key Features of a Containerized Water Treatment Plant

Containerised water treatment plants are a smart choice for clean water solutions. They come with a range of features that make them efficient and easy to use. Here are the main features that set them apart:

Easy Setup

These plants are like ready-to-use kits. Once they arrive at the site, they can be set up quickly and easily. No complicated installation process is needed.

Minimal Construction Work

Unlike regular treatment plants, containerized ones need only a simple foundation. This means less hassle and fewer costs for construction.

Perfect for Construction Sites

They’re a real help on construction sites. They provide clean water right where it’s needed, without the need for big, complex setups.

Moveable

These plants can be moved from one place to another. This makes them great for temporary projects, emergencies, or when water needs change.

Tough and Durable

They’re built strong to handle tough jobs. These plants are made to last, even in rough conditions.

Customizable

You can add or remove units as needed. This makes them a flexible and cost-effective choice for different situations.

Works Anywhere

They’re great for places that are hard to reach. These plants can operate on their own, making them a big help for communities in remote areas.

Easy to Use

Setting up and running these plants is a breeze. They come with clear instructions, and the controls are user-friendly for operators.

Ready to Go

They arrive fully equipped and ready for action. Everything needed, from pumps to filters and controls, is included. This means they can be up and running in no time.

Applications for Containerized Water Treatment Units

Containerized water treatment plants find their value in a wide range of scenarios due to their versatility and efficiency. Here are some of the key applications where these units prove to be invaluable:

Construction Sites

Containerized units are a boon for construction projects. They provide a readily available source of clean water on-site, eliminating the need for complex infrastructure setups.

Remote and Off-Grid Areas

In remote or off-grid locations where access to clean water is limited, containerized units offer a self-contained solution. They can operate independently, making them crucial for communities in hard-to-reach areas.

Emergency Response

During emergencies like natural disasters or crises, quick access to clean water is essential. Containerized units can be swiftly deployed to provide immediate relief to affected areas.

Military Operations

Military operations often take place in diverse and challenging environments. Containerized water treatment plants offer a compact and reliable solution for ensuring a safe water supply in the field.

Humanitarian Aid Missions

In humanitarian efforts, providing access to clean water is a top priority. Containerized units are easily transportable and can be set up rapidly in areas where there is an urgent need for clean water.

Mining and Resource Extraction

In resource extraction industries like mining, having a reliable water treatment solution is crucial. Containerized units can be stationed at mining sites to ensure a steady and safe water supply.

Temporary Settlements and Camps

For temporary settlements, such as refugee camps or event sites, containerized water treatment plants offer a practical and efficient means of providing clean water to a large number of people.

Industrial Sites

Industrial facilities often require specialized water treatment processes. Containerized units can be customized to meet specific industrial water treatment needs, ensuring compliance with environmental regulations.

Mobile and Expeditionary Units

Containerized units are designed to be easily transportable. This makes them suitable for mobile applications, such as expeditions or field research projects, where a reliable source of clean water is essential.

Where can I buy containerized Water Treatment Units?

You can purchase high-quality containerized Water Treatment Units from Refinar East Africa. For inquiries and orders, you can reach out to us through:

- Phone: 0707075702

- Email: info@refinareastafrica.com

At Refinar East Africa we specialize in providing reliable water treatment solutions, ensuring access to clean and safe water in various applications. Feel free to contact us for further information and assistance with your water treatment needs.